Flat rotary disk

Related recommendations : Double-sided CNC Boring Lathe Four-station Butterfly Valve Processing Machine Three-sided CNC Boring Lathe

Catalog browsing and downloading

CNC Flat rotary disk is a widely used equipment in the field of CNC machining.

1、 Structural characteristics

Flat shape

Its main structural feature is a flat shape. This shape design allows the rotating disc to have a lower center of gravity during operation, making it more stable to be installed on the machine tool worktable. Compared with traditional higher rotating devices, the centrifugal force generated by flat rotating discs during high-speed rotation has a relatively small impact on the overall stability of the machine tool.

Rotating mechanism

Internally equipped with high-precision rotating mechanisms, typically consisting of motors, reducers, and high-precision bearings. The motor provides power and adjusts the rotational speed through a reducer to meet different processing requirements. High precision bearings ensure the accuracy and stability of rotation, enabling precise angular positioning with a turning accuracy of up to micrometer level. For example, in some precision mold processing, it is necessary to rotate the workpiece at a very precise angle, and the CNC flat rotating disc can take advantage of its high-precision rotation.

Installation interface

There are standard installation interfaces on the surface and sides for fixing the workpiece or fixture being processed. The size and specifications of these interfaces usually follow the standards of the machine tool industry, making it convenient for users to install workpieces of various shapes and sizes according to different machining tasks. For example, common fixtures such as three jaw chucks and four jaw chucks can be installed through T-slots or screw holes.

2、 Working principle

Numerical Control System Control

The CNC flat rotating disc is controlled by a CNC system. The CNC system sends command signals to the drive motor of the rotating disk to control the speed and direction of the motor. Through pre written numerical control programs, the rotation angle and speed of the rotating disk can be precisely controlled. For example, when processing complex curved parts, the CNC program can accurately control the rotating disk to rotate at a certain angle step size according to the geometric requirements of the part, and match the motion trajectory of the tool to process the parts that meet the requirements.

Linkage processing

It can be linked with other coordinate axes of the machine tool (such as X axis, Y axis, Z axis) for machining. In some complex parts machining, while the tool moves along the X, Y, and Z axis directions, the rotating disk also rotates according to a certain rule, achieving multi axis linkage machining. This processing method can greatly improve the flexibility and accuracy of machining. For example, in the machining of aerospace parts, for parts such as blades with complex shapes and high-precision requirements, the linkage processing of CNC flat rotating disks and other coordinate axes is crucial.

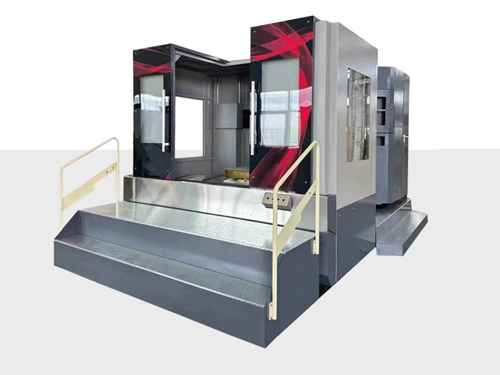

Introduction to Horizontal Machining Centers: Horizontal machining centers are suitable for...

Characteristics and advantages of machine tools The machine tool is controlled by a numeric...

Characteristics and advantages of Double sided Cnc Boring Lathe: The machine tool is contro...

Characteristics and advantages of machine tools The machine tool is controlled by a numeric...