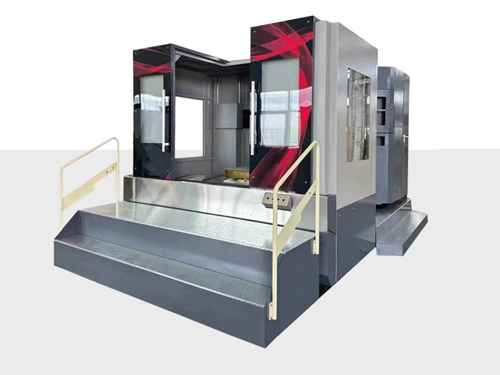

Three-sided Cnc Boring Lathe

Related recommendations : Double-sided CNC Boring Lathe Four-station Butterfly Valve Processing Machine Three-sided CNC Boring Lathe

Catalog browsing and downloading

Characteristics and advantages of machine tools

The machine tool is controlled by a numerical control system, which is easy and fast to operate. Simultaneous processing of three surfaces is fast, improving processing efficiency, saving labor, and reducing costs.

1. The machine tool is suitable for processing various surfaces such as lubrication doors, pipe fittings, and fire hydrants that require parallelism and perpendicularity. It has high processing efficiency, uniform processing dimensions, and easy operation.

2. High processing efficiency, the machine tool can complete the machining of three outer rings, planes or holes at the same time by using three power heads to work simultaneously during the machining process.

3. Reducing manual labor, one dedicated machine is equivalent to the efficiency of three ordinary devices, and one person can operate 2-3 dedicated machines.

4. The uniformity of machining dimensions is high, and this machine tool is completely controlled by a CNC system. Only one tool alignment is needed to repeatedly machine the same type of workpiece, thereby improving the uniformity of dimensions.

5. Easy to operate, this special machine is completely controlled by a CNC system. Experienced CNC operators or those with a foundation in machine tool processing can learn it at a glance.

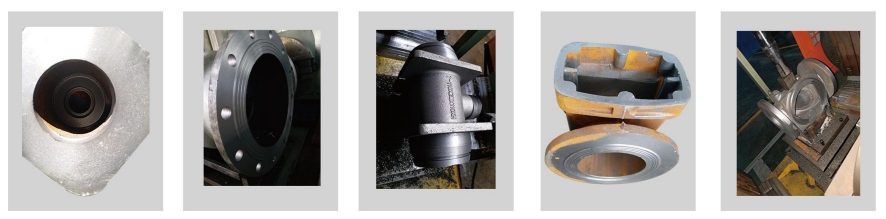

Processed products:

specifications:

| project | Machine tool specifications | YC lll C300HT | YC lll C400HT | YC lll C600HT | YC lll C800HT | |

| technical specifications | block type (mm) | φ460 | φ580 | φ840 | φ1025 | |

| Maximum processing length (mm) | 600 | 800 | 1000 | 1100 | ||

| Minimum processing length (mm) | 200 | 300 | 300 | 400 | ||

| Maximum machining size from the middle flange to the center(mm) | 400 | 600 | 700 | 900 | ||

| Minimum machining size from the middle flange to the center(mm) | 150 | 200 | 200 | 250 | ||

| X-axis travel (mm) | 170 | 270 | 450 | 570 | ||

| Z-axis travel (mm) | 280 | 395 | 450 | 450 | ||

| Processing accuracy | Coaxiality ( mm ) | ≤0.1 | ≤0.1 | ≤0.15 | ≤0.2 | |

| Parallelism(mm) | ≤0.1 | ≤0.1 | ≤0.15 | ≤0.2 | ||

| verticality ( mm ) | ≤0.1 | ≤0.1 | ≤0.15 | ≤0.2 | ||

| Surface roughness | 6.3 | 6.3 | 6.3 | 6.3 | ||

| Main shaft drive | Transmission mode (gear shifting) | 4-speed transmission | 3-speed transmission | 2-speed transmission | 3-speed transmission | |

| Spindle speed range (r/min) | 72-256 | 69-157 | 32-47 | 43-87 | ||

| Spindle motor model | YE2-132M-6-5.5KW | YE2-132M-6-5.5KW | YE2-160L-8-7.5KW | YE2-180L-8-11KW | ||

| CNC control system (optional) | Nanjing Huaxing - Servo System Guangzhou CNC - Servo System Nanjing Huaxing - Stepper System Guangzhou CNC - Stepper System | |||||

| Feed form ( optional ) | Stepper motor | 24N.m | 24N.m | 35N.m | 50N.m | |

| servo motor | 7.7N.m | 7.7N.m | 10N.m | 15N.m | ||

| Machine tool appearance | Full protection | Machine tool dimensions (length X width X height mm) | 3800X2700X1700 | 4500X3300X2200 | 5000X3600X2200 | 5400X3900X2500 |

| Simple protection | Machine tool dimensions (length X width X height mm) | 3600X2600X1700 | 4350X3200X2200 | 4800X3500X2200 | 5200X3800X2500 | |

| Machine weight(kg) | 4500 | 6500 | 8000 | 11000 | ||

Introduction to Horizontal Machining Centers: Horizontal machining centers are suitable for...

Characteristics and advantages of machine tools The machine tool is controlled by a numeric...

Characteristics and advantages of Double sided Cnc Boring Lathe: The machine tool is contro...

Characteristics and advantages of machine tools The machine tool is controlled by a numeric...