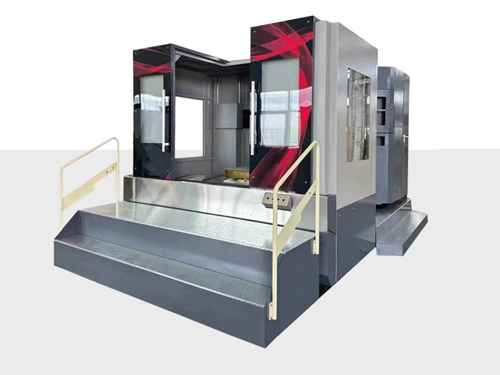

Horizontal Drilling And Twisting Machine

Related recommendations : Single-sided Multi-hole Drilling Machine Double-sided Multi-hole Drilling Machine Three-sided Multi-hole Drilling Machine

Structure of Horizontal Drilling And Twisting Machine:

1.The bed,column,saddle,worktable and spindle box are made of gray cast iron with stable performance and good quality,and have good thermal stability;

2.The spindle assembly with appropriate precision has good precision and balance,and has a high-rigidity matching structure;

3.Three sets of fine linear guides are used in the Z direction;

4.Two sets of fine linear guides are used in the spindle box(Y direction)and the worktable(X direction);

5.The ball screws are pre-stretched,so that the transmission rigidity of the three axes is good,the precision is stable,and the transmission is smooth;

6.Equipped with a centralized lubrication device,the lubrication is sufficient.

Processing and use of horizontal drilling and twisting machine:

1.The spindle box moves in the X and Z directions,and the worktable moves in the Y direction.It is suitable for boring,milling and other multi-process processing of small and medium-sized parts.

2.The worktable moves in the X and Z directions,and the spindle box moves in the Y direction.The spindle box has two forms of positive hanging and side hanging on the column.Suitable for boring,milling and other multi-process processing of medium-sized complex parts.

3.The spindle box is hung on the side and the column,and the spindle box moves in the Y and Z directions.This layout is similar to the planer-type horizontal milling and boring machine,and the worktable moves in the X direction.Suitable for boring,milling and other multi-process processing of medium-sized parts.

Scope of application of horizontal processing drilling and twisting machine:

Horizontal processing drilling and twisting machine refers to a processing machine tool with the spindle axis parallel to the worktable.It can process larger parts and can be indexed and rotated.It is suitable for multi-process processing such as milling,drilling,boring,reaming,tapping,two-dimensional and three-dimensional curved surfaces of multiple working surfaces of parts.It has good performance in completing the box body hole system and plane processing in one clamping.It is also particularly suitable for the turning and boring processing of box body holes.It is widely used in automobiles,internal combustion engines,pumps and valves,printing and dyeing industries,general machinery and other industries.

Introduction to Horizontal Machining Centers: Horizontal machining centers are suitable for...

Characteristics and advantages of machine tools The machine tool is controlled by a numeric...

Characteristics and advantages of Double sided Cnc Boring Lathe: The machine tool is contro...

Characteristics and advantages of machine tools The machine tool is controlled by a numeric...