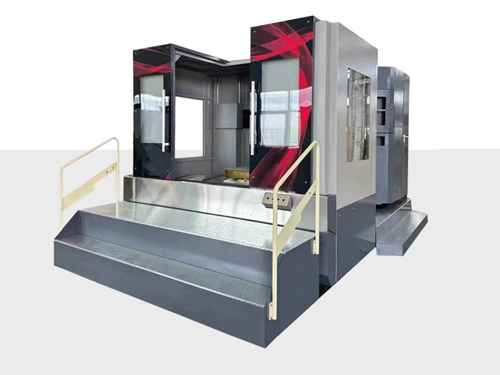

Double-sided Multi-hole Drill

Related recommendations : Four-station Butterfly Valve Processing Machine Drilling And Tapping Machine Single-sided Multi-hole Drilling Machine

Characteristics and advantages of double-sided Multi-hole Drill:

Simultaneous processing of multiple holes on two flange surfaces results in high processing efficiency, reduced manual labor, high uniformity of processing dimensions, and easy operation.

1. This machine tool is suitable for various valve fittings: it can process any valve body with two flange faces on the same axis, or any side can be processed separately.

2. High processing efficiency: During the machining process, the machine tool uses the power head to simultaneously complete the drilling process of multiple holes on the flange, with a cycle time of less than 2 minutes

3. Reduce labor: Traditional drilling machine workers need to use molds to process one hole at a time, which wastes time. This machine tool can simultaneously process multiple holes on two flange surfaces, and one employee can operate multiple machine tools at the same time, thereby improving efficiency.

4. High uniformity of machining dimensions: only one adjustment is required, and subsequent drilling work can be easily completed by simply installing the workpiece.

5. Easy to operate: Anyone without machining experience can learn this machine tool at once.

Processed products:

specifications:

| project | Machine tool specifications | YC ll Z200HT | YC ll Z300HT | YC ll Z400HT | YC ll Z600HT |

| technical specifications | Maximum drilling center distance (mm) | φ295 | φ410 | φ525 | φ770 |

| Maximum processing length (mm) | 600 | 800 | 800 | 1000 | |

| Minimum processing length (mm) | 200 | 200 | 300 | 300 | |

| Travel distance (mm) | 340 | 450 | 450 | 450 | |

| Drill bit connection method (Mohs taper shank) | Mo Formula 2 # | Mo Formula 2 #/Mo Formula 3# | Mo Formula 2 #/Mo Formula 3# | Mo Formula 2 #/Mo Formula 3# | |

| Machining accuracy | Position accuracy (mm) | ≤0.5 | ≤0.6 | ≤0.8 | ≤1 |

| Surface roughness | 12.5 | 12.5 | 12.5 | 12.5 | |

| Main shaft drive | Transmission form (gear shifting) | 2-speed transmission | 2-speed transmission | 2-speed transmission | |

| Spindle speed range (r/min) | 225/286 | 197/223 | 159/231 | 11KWgear motor | |

| Spindle motor model | YE2-132M-6-5.5KW | YE2-132M-6-5.5KW | YE2-132M-6-7.5KW | YE2-180L-8-11KW | |

| Numerical Control System | PLC | ||||

| Feed form | Hydraulic transmission | ||||

| Machine tool appearance | Machine tool dimensions (length X width X height mm) | 2800X1000x1500 | 3200X1200X1700 | 3300X1200X1700 | 3400X1500X2000 |

| Machine weight (kg) | 1500 | 1800 | 2200 | 3000 | |

Introduction to Horizontal Machining Centers: Horizontal machining centers are suitable for...

Characteristics and advantages of machine tools The machine tool is controlled by a numeric...

Characteristics and advantages of Double sided Cnc Boring Lathe: The machine tool is contro...

Characteristics and advantages of machine tools The machine tool is controlled by a numeric...