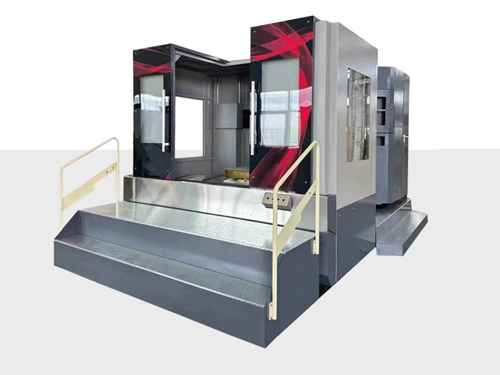

Full protection drilling and attacking machine

Related recommendations : Double-sided CNC Boring Lathe Four-station Butterfly Valve Processing Machine Three-sided CNC Boring Lathe

Catalog browsing and downloading

Characteristics and advantages of full protection drilling and attacking machine

Simultaneous processing of multiple threaded holes on the same plane, high processing efficiency, reduced manual labor, high uniformity of processing dimensions, and easy operation.

1. The machine tool is suitable for various valve fittings: the machine tool uses a cross coupling to drive the spline shaft transmission, and the position adjustment range of the drill rod is large. The machine tool can process products with multiple threaded holes on the same plane as the valve mouth.

2. High processing efficiency: During the machining process, the machine tool uses the longitudinal feed of the first power head to complete the drilling process of the thread pattern. The workpiece is moved from the transverse worktable to the second station, and the longitudinal feed of the second power head completes the threading process of the thread. The required time is 1-2 minutes.

3. Reduce manual labor: Traditional tapping requires two processes, namely drilling the threaded bottom hole and tapping, and requires the use of grinding tools to process each hole one by one, wasting time. This machine tool can complete the drilling and tapping of multiple holes in one clamping, with very high work efficiency.

4. High uniformity of machining dimensions: After the first adjustment is completed, only the workpiece needs to be clamped to cycle the drilling and tapping work.

5. Easy to operate: This machine tool is easy to operate, and anyone with or without experience can learn it at a glance.

Processed products:

specifications:

| project | Machine tool specifications | YCZG200HT | YCZG300HT |

| technical specifications | Maximum drilling center distance (mm) | φ230 | φ400 |

| Maximum machining size from middle flange to center (mm) | 300 | 400 | |

| Minimum machining size from middle flange to center (mm) | 150 | 150 | |

| Power box travel (mm) | 180 | 320 | |

| Mobile workbench travel (mm) | 460 | 460 | |

| Machining accuracy | Drill bit connection method | ER clamp | ER clamp |

| Positional accuracy ( m m ) | ≤0.2 | ≤0.2 | |

| Main shaft drive | Surface roughness | 12.5 | 12.5 |

| Range of spindle speed(r/min) | 400/100 | 300/100 | |

| Spindle motor model | YE2-132M-6-2.2KW | YE2-132M-6-3KW | |

| control system | PLC | ||

| Feed form | Hydraulic transmission/cylinder transmission | ||

| Machine tool appearance | Machine tool external dimensions(Length X Width X Height mm) | 2300X1700X1700 | 2500X1900X1800 |

| Machine weight (kg) | 1100 | 1800 | |

Introduction to Horizontal Machining Centers: Horizontal machining centers are suitable for...

Characteristics and advantages of machine tools The machine tool is controlled by a numeric...

Characteristics and advantages of Double sided Cnc Boring Lathe: The machine tool is contro...

Characteristics and advantages of machine tools The machine tool is controlled by a numeric...