Groove butterfly valve machining machine

Related recommendations : Double-sided CNC Boring Lathe Four-station Butterfly Valve Processing Machine Three-sided CNC Boring Lathe

Catalog browsing and downloading

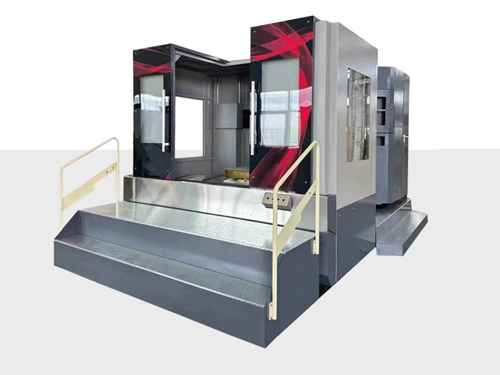

Introduction to groove butterfly valve machining machine tool

The machine tool is controlled by a numerical control system, which is easy and fast to operate. Simultaneous processing of three surfaces is fast, improving processing efficiency, saving labor, and reducing costs.

This machine tool is a groove butterfly valve processing machine, which can meet the full sequence processing of groove butterfly valves.

The machine tool adopts a horizontal three sided form, with boring power heads at both ends, and a six station power turret and cross slide table arrangement at the center. The six station turret can accommodate six cutting tools.

By changing the tool, processes such as workpiece, outer circle, end face, end face, drilling, and expanding valve stem holes can be met.

Processed products:

Specifications:

| project | Machine tool specifications | YCGCZJ-200HT |

| technical specifications | The diameter range of the workpiece being machined on the boring machine head | φ60-φ220 |

| Range of length of processed workpiece | -200 | |

| The length range from the middle end face to the center of both ends of the processed workpiece | 75-210 | |

| Spindle diameter | φ100mm | |

| Connection method of power turret handle | BT40 | |

| Boring machine head cutterhead X-direction travel | 70mm | |

| Effective Z-axis travel of the sliding table at both ends of the boring machine head | 350mm | |

| Power turret center power turret sliding table X-axis travel | 400mm | |

| Power turret center power turret slide Z-axis travel | 500mm | |

| Power turret servo main motor | ZMYA-380-200M-5.5KW | |

| Three asynchronous motors for boring locomotive head | Y132M-6N=5.5kwn=960rpm | |

| Power turret workstation | 6 workstations | |

| Machining accuracy | Coaxiality of left and right heads | ≤0.1 |

| Parallelism of left and right heads | ≤0.1 | |

| Verticality of left and right heads to the middle head | ≤0.1 | |

| Coaxiality of valve stem hole | ≤0.2 | |

| Main shaft drive | Knife tower transmission form | Timing belt |

| Boring machine head transmission form | gear drive | |

| Range of spindle speed for turret | 0-1500rp/min(Servo speed regulation) | |

| Boring machine head spindle speed range (r/min) | 68-108-157-229rp/min < (Four speed mechanical transmission) | |

| CNC control system (optional) | Nanjing Dafeng servo system, Guangshu servo system, etc | |

| Feed form | servo motor | 7.7N.M |

| Machine, bed shape (optional) | Full protection, high protection, and simple protection | |

| Machine weight (kg) | 5300 | |

Introduction to Horizontal Machining Centers: Horizontal machining centers are suitable for...

Characteristics and advantages of machine tools The machine tool is controlled by a numeric...

Characteristics and advantages of Double sided Cnc Boring Lathe: The machine tool is contro...

Characteristics and advantages of machine tools The machine tool is controlled by a numeric...