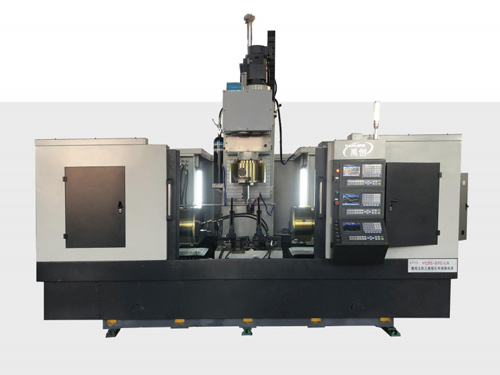

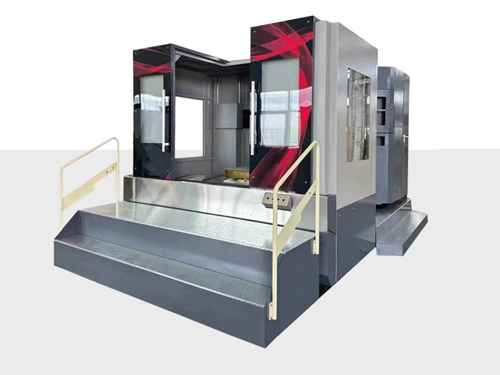

Vertical and horizontal three-side CNC boring lathe

Related recommendations : Double-sided CNC Boring Lathe Four-station Butterfly Valve Processing Machine Three-sided CNC Boring Lathe

Catalog browsing and downloading

Vertical and horizontal three-side CNC boring lathe is a high-precision and high-efficiency metal processing machine tool.It combines CNC technology,boring function,and turning function,and can perform machining operations in three main directions(usually X,Y,Z axes).

Vertical and horizontal"means that the machine tool can perform both vertical machining(with the tool perpendicular to the workpiece surface)and horizontal machining(with the tool parallel to the workpiece surface).This multifunctional processing method enables machine tools to adapt to the processing of various complex shaped parts.

Structural characteristics

Bed:The bed is the basic component of the machine tool,with sufficient rigidity and stability.It provides installation foundation for other components and is usually made of high-quality cast iron to reduce vibration during the machining process.

Spindle system:

Including vertical and horizontal axes.Vertical shafts are mainly used for vertical machining,which can achieve high-speed rotation and provide power for boring or turning tools.Its speed range is wide and can be adjusted according to different processing materials and process requirements.

The horizontal axis is used for horizontal machining and also has high-precision rotation accuracy,ensuring high surface quality of the machined workpiece.

Knife holder system:

The tool holder can be equipped with various cutting tools,such as boring tools,turning tools,drill bits,etc.The tool changing method of the tool holder is usually automatic,and through the instructions of the CNC system,the tool can be quickly and accurately replaced to improve machining efficiency.

The tool holder has high motion accuracy in three coordinate axis directions,generally using high-precision ball screw transmission and equipped with linear guides to ensure that the tool can move accurately to the machining position according to the preset program.

Numerical Control System:

This is the core part of the vertical and horizontal three sided CNC boring lathe.The numerical control system can receive machining programs written by users and convert them into motion commands for various coordinate axes,as well as control commands for spindle speed,feed rate,etc.

Advanced CNC systems have graphical programming interfaces,tool path simulation,and other functions,making it convenient for users to program and debug.At the same time,the CNC system can also monitor the real-time operation status of the machine tool.Once a fault or abnormal situation occurs,it will promptly alarm and take corresponding protective measures.

Processing advantages

High machining accuracy:Due to the use of CNC technology and high-precision mechanical structures,it is possible to achieve micrometer level or even higher machining accuracy.For example,when processing precision molds or aerospace components,the dimensional accuracy and shape accuracy of the parts can be guaranteed to meet strict quality requirements.

Wide processing range:

It can process various shapes of rotating parts,such as shafts,disks,sleeves,etc.For parts with complex internal cavity structures,such as engine cylinder blocks,valve bodies,etc.,boring machining can effectively remove materials and form the desired shape.

Capable of processing various surfaces such as inner and outer cylindrical surfaces,conical surfaces,flat surfaces,and threads,achieving the combination of multiple processing techniques.

High production efficiency:

The automatic tool changing system and CNC programming greatly reduce the auxiliary time during the machining process.Machine tools can perform various machining operations continuously without frequent manual intervention.

By optimizing machining parameters and tool paths,cutting efficiency can be improved and the machining cycle of parts can be shortened.

application area

Aerospace field:used for processing aircraft engine components,landing gear components,aviation structural components,etc.These components have extremely high requirements for material performance,dimensional accuracy,and shape accuracy,and the vertical and horizontal three sided CNC boring lathe can meet their machining needs.

In the field of automobile manufacturing:processing key components such as engine cylinder blocks,crankshafts,and transmission housings.Its high-precision and high-efficiency processing capabilities help improve the quality and production efficiency of automotive components.

Mold manufacturing field:manufacturing various stamping molds,injection molds,etc.In mold processing,precise machining of complex cavities and cores is required.Vertical and horizontal three sided CNC boring lathes can leverage their advantages to manufacture high-quality molds.

In the field of mechanical manufacturing,it is widely used in the processing of various mechanical parts,such as pump bodies,valves,machine tool components,etc.It can flexibly process according to different part design requirements,improving the overall quality of mechanical products.

Processed products:

Introduction to Horizontal Machining Centers: Horizontal machining centers are suitable for...

Characteristics and advantages of machine tools The machine tool is controlled by a numeric...

Characteristics and advantages of Double sided Cnc Boring Lathe: The machine tool is contro...

Characteristics and advantages of machine tools The machine tool is controlled by a numeric...